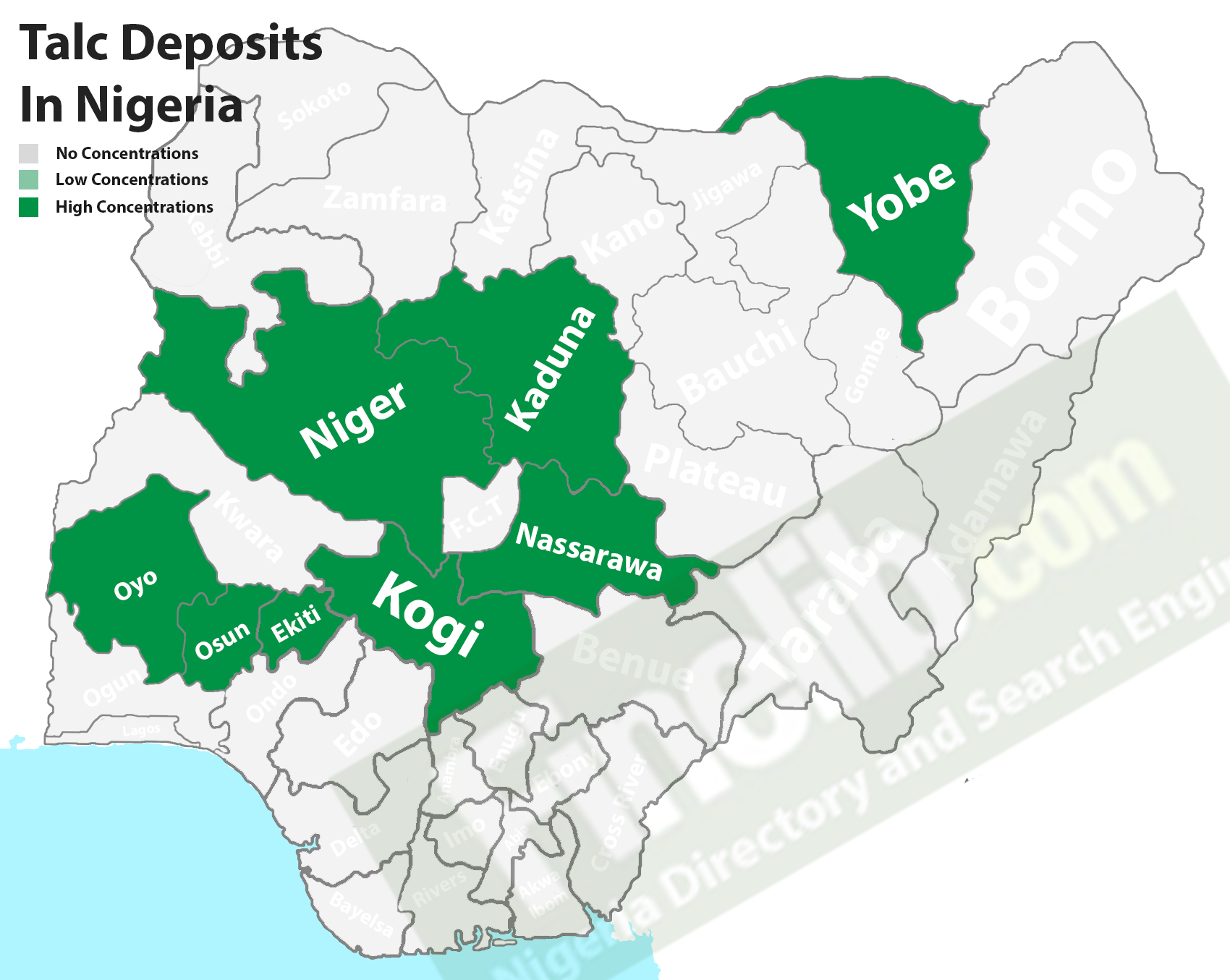

Talc Deposits In Nigeria And Its Mining Operations

Talc can be found in Western Africa such as Nigeria, and the states with these mineral deposits include Kogi, Kaduna, Niger, Ekiti, Nasarawa, Osun, Oyo, and Yobe states.

Talc is characterized as a soft mineral with can be white in color, pale green, or grey and feels greasy when touched, it is comprised of hydrated magnesium silicate and occurs as translucent masses. The mineral is mostly made up of magnesium, silicon, and oxygen elements.

It is found mostly in metamorphic rocks and is locked deep within the rock and can be otherwise called metamorphic mineral as a result of its formation from metamorphism of magnesia minerals such as pyroxene, serpentine, olivine, and amphibole in the presence of carbon dioxide (Co2) and water (H2O).

The formation of Talc is primarily through the hydration and carbonation process which is a reaction between Serpentine + carbon dioxide → talc + magnesite + water

Talc can also be formed through the metamorphic reaction from quartz and magnesian chlorite in eclogite and blueschist metamorphism.

The metamorphic reaction can be seen below:

chlorite + quartz → kyanite + talc + water

The production processes of talc, from mining to treatment are explained below;

Mining

Talc mining can be done using an open-pit method or a conventional cut method. The mining of talc is mostly done by using open-pit operation since its mainly found deep down into metamorphic rocks, the rock which serves as a covering to the mineral is removed by the use of giant shovels, and the conventional cut method combined with cemented backfill method can also be used for underground mine specifically.

Extraction

When the talc ore has been identified, the mineral is then extracted using hydraulic backhoe shovels or some other related machinery. When both the talc ores are being extracted from the seam and during the main production process, the ores are sorted into their different contents accordingly.

Sorting

In sorting the talc ores these techniques can be used; friction sorting, image analysis technology, floatation, and others. After sorting, the ores are dried and finely grounded into micronized particles.

Milling

In this stage, the type of ore determines the milling technology to be used, but to obtain a better and yielding result in terms of the size and the application, varieties of techniques can be used. Such techniques include but are not limited to steam milling, compressed air, and impact milling.

Treatment

After the milling process, talc can be treated depending on the grade and applications which might include talc for fertilizers, cosmetics, rubber processing, pharmaceuticals, and more.

Other Uses of Talc

- The soapstone is used for sinks, stoves, soaps, crayons, and more, such as electrical switchboards.

- Ground talc is used as a lubricant in applications where high temperatures are involved.

- Talc powder is used as a carrier for insecticides and fungicides.

- It is used to reduce wear on application equipment.

- Talc is resistant to heat, acid, and electricity, and of this, it is mainly used for lab countertop surfaces.

- Talc is used in ceramics, plastics, paint, paper, antiperspirants, roofing materials.

- Talc is used in cosmetics such as talcum powder, baby powder, and astringent powder used to prevent rashes on the area covered by a diaper.